In the tunnel construction process, poor support often leads to significant deformation of the surrounding rock, posing a threat to the safety of construction personnel and resulting in financial losses. Rock bolt anchoring, as an active support technique, allows for minor deformations in the tunnel’s surrounding rock while fully exploiting the self-stabilizing capacity of the rock.

Anchor bolt reinforcement is a flexible engineering solution primarily relying on friction between the anchor bolt and the surrounding soil. It enhances the integrity of the rock and controls deformations post-excavation to prevent sudden stress releases. Different models of anchor bolt theories are applied based on the geological conditions and the type of anchor bolts used.

1. Suspension Theory

Suspension theory, introduced in 1952, is designed to connect loose and unstable rock layers surrounding the tunnel with anchor bolts. This connection forms an overall structure to suspend and prevent the falling of rock fragments. This approach effectively stabilizes the tunnel roof by offsetting the rock’s self-weight using the friction between the anchor bolt and the rock, even when there are no firm rock layers in the upper part of the surrounding rock. When this functionality is the primary focus of tunnel support, anchor bolt calculations should consider the weight-bearing capacity of all unstable patterns.

2. Span Reduction Theory

Inserting anchor bolts in the tunnel’s roof decreases the tunnel span, which, in turn, reduces stress on the tunnel roof rock, helping to maintain tunnel stability.

3. Composite Beam Theory

The composite beam theory is applied to supplement suspension theory. It is particularly useful when there’s a risk of sliding along the rock layers. Anchor bolts bind certain thicknesses of rock layers together to prevent delamination effectively. It increases the rock’s shear strength by utilizing the lateral load-bearing capacity of the anchor bolt. Moreover, it provides axial pressure on the stratified rock layers, significantly enhancing their interlayer bonding and friction. This prevents potential slippage between rock layers.

4. Integral Reinforcement Theory

Integral reinforcement theory involves the systematic placement of a group of rock bolts within a designated area of weakened surrounding rock during tunnel arch excavation. This process relies on compression and bonding to strengthen the surrounding rock, forming a load-bearing ring. Typically, the rock mass around the rock bolts forms a conical, cylindrical compression zone with rounded ends under the influence of rock bolt pre-stressing. The compression zones between the rock bolts interconnect, creating a uniform, thick compression band. The rocks near the compression band experience three-directional stress due to the rock bolts’ support and pre-stressing, significantly enhancing rock strength and resulting in the formation of a stable rock mass capable of withstanding specific loads, known as the load-bearing ring.

As illustrated in Figure 4, this load-bearing ring enhances radial stress in the rock mass from δ1=0 to δ1, raises the rock’s shear strength from R to δ1, and increases the rock’s shear strength from T1 to T2 when sliding along the rock failure surface. This integral reinforcement action augments the unloading effect on the rock mass around the tunnel, reducing the load on the tunnel lining.

5. Neutral Point Theory

The neutral point theory involves in-situ monitoring of the anchor bolts. It introduces concepts like the “neutral point,” “pull-out length,” and “anchoring length,” derived from the in-situ monitoring results.

6. Rock Loose Circle Support Theory

The rock loose circle support theory is based on the objective existence of loose and broken zones in the surrounding rock. It is a consequence of rock stress exceeding the surrounding rock’s strength after tunnel excavation.

To meet diverse engineering demands, various new types of anchor bolts have been introduced. They employ innovative materials and structural designs to enhance anchoring performance, effectively coping with complex geological conditions. The success of anchor bolt anchoring doesn’t solely depend on the bolts themselves but also on the strength and bonding effectiveness of the anchoring material. It’s closely related to the anchor bolt’s anchoring method.

Depending on the load transmission mechanism, common anchor bolts can be divided into five categories:

Adhesive Anchoring: Anchor bolts are anchored through bonding with adhesive materials like cement grout rock bolts, hollow grout rock bolts, or self-drilling anchor bolts.

Mechanical Anchoring or Bonded Anchoring: Rock bolts anchor within the rock formation at the bottom of the borehole. Rock bolts impose radial constraints on the surrounding rock by the borehole and nut baseplate, reducing the span of the tunnel.

Friction-Based Anchoring: Rock bolts prevent rock displacement by generating static friction between the borehole wall and the rock bolt. They enhance the surrounding rock’s stability.

Pre-stressed Anchor Bolts: These are pre-stressed before anchoring in the borehole. Pre-stressed rock bolts significantly improve the frictional resistance between rock strata, enhancing rock stability.

Enhanced Anchoring: Improved anchoring mechanisms modify conventional rock bolts to adapt to complex geological conditions, such as inflatable rock bolts and expansion anchor rods.

Self-drilling anchor bolts offer an integrated solution for challenging geological conditions, such as loose accumulations and severe rock weathering, ensuring both high construction efficiency and excellent anchoring effectiveness.

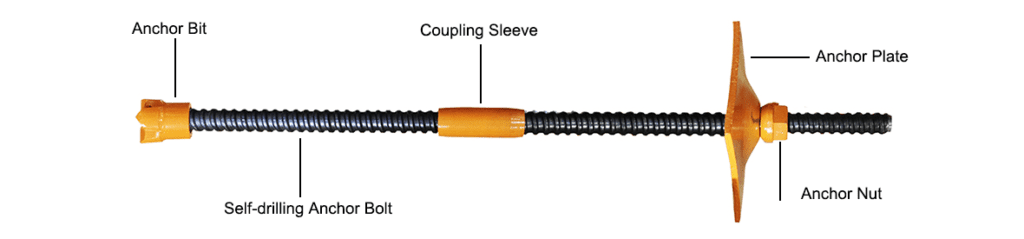

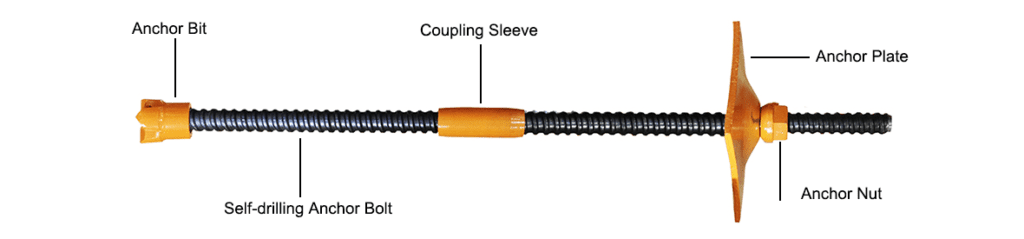

The self-drilling anchor bolt’s drilling head exhibits formidable penetration capabilities, enabling it to traverse various rock types. It eliminates the need for special wall protection techniques, such as casing or grouting, common in traditional drilling methods. This multifunctional approach integrates drilling, grouting, and anchoring into a seamless operation. The entire length of the anchor bolt features a wave-threaded surface, facilitating the installation of drill heads, coupling sleeves, and nuts. Moreover, it allows for custom cutting and extension, making it suitable for construction in confined spaces.

Furthermore, the hollow section of the anchor bolt serves as a grouting channel, enabling injection from the inside to the outside. By installing grout stops, pressure grouting can be performed, ensuring complete grout filling without overflow, while washers and nuts evenly distribute stress to the rock surface at the end of the anchor bolt.

The self-drilling anchor bolt is equipped with a disposable, user-friendly drilling head that can autonomously perform drilling tasks under external force. Its corrugated surface effectively resolves debris blockages, hole collapses, and jamming, enhancing the rock bolt’s gripping power. High-strength drilling rods significantly reinforce the stability of tunnel or slope projects. The hollow section of the anchor bolt serves as a grouting channel, enabling the injection of cement slurry from inside to outside. The anchor bolt’s external end features grout stops and bearing plates, effectively preventing grout overflow and ensuring complete grout filling between the anchor bolt and borehole wall. This ensures uniform transmission of shear and tensile stresses along the entire length of the anchor bolt, fortifying the rock within the anchoring area. If necessary, pressure grouting can be executed, allowing grout to infiltrate and further strengthen the rock around the anchor bolt.

Once the grout solidifies, tightening the nut with a torque wrench produces approximately 10 kN of bearing plate resistance, forming a spherical pressure zone at the anchor bolt’s end similar to mechanical rock bolts. This enables the control of early deformations post-excavation, preventing the fall of fractured rock fragments, and significantly reinforcing the stability of tunnel or slope projects.

In soft, fragmented, or challenging formation conditions, the self-drilling anchor bolt combines the drill rod with the hollow anchor rod body, leaving the drilling head embedded in the formation. It can be conveniently extended by coupling sleeves, fundamentally addressing the issue of being unable to install anchor bolts or achieve the required length in poor geological conditions.

In conclusion, self-drilling anchor bolts ensure not only complete grout filling within the gap between the rock bolt and the borehole wall but also, thanks to the presence of the drilling head, grout stops, and connecting sleeves, enable the rock bolt to be centered within the borehole. This ensures a uniform protective layer thickness, ultimately enhancing the durability of the rock bolt.