The self-drilling anchor system mainly consists of a hollow threaded anchor rod, a disposable drill bit, and some other accessories. This system is capable of performing drilling, anchoring, and grouting simultaneously.

Slope remediation projects are common in various areas such as highways, railways, and water projects, and the construction methods can vary. In some slope protection projects, the geological conditions are complex, making it difficult to create holes for conventional anchor rod support, resulting in complex procedures. However, the use of self-drilling anchor tools can effectively solve the problem of difficult drilling caused by loose soil and rock formations. Moreover, self-drilling anchor tools, due to their structural characteristics, offer advantages of simplified construction, ease of operation, and high reliability. They are widely applicable in the support of slopes with loose soil and rock formations.

Self-drilling anchor bolt is a hollow rod that serves as both a drilling rod and a grouting pipe. Prior to grouting, it can function as a dust flushing pipe to remove the dust generated during rock drilling. During grouting, the grout is injected through the hollow anchor rod, spraying out from the drill bit to fill the drill holes and fractures in the surrounding formation. This process solidifies the anchor bolt with the surrounding soil, forming a cement column that reinforces the structure. The self-drilling anchor tool is a multifunctional support product that combines drilling, grouting, and anchoring. The length of the self-drilling anchor bolt can be flexible, and it has the capability to connect with extension rods. Compared to conventional anchor rods, self-drilling anchor bolts possess their own unique characteristics and advantages.

Construction of conventional anchor rods

Construction of conventional anchor rods involves drilling the hole, removing the drill rods, and then proceeding with either grouting before installing the anchor rod or installing the anchor rod before grouting. This process presents some common challenges that are difficult to solve, such as:

- Insufficient removal of rock debris during drilling or poor geological conditions at the drilling site can lead to blockage, making grouting difficult.

- Inadequate sealing at the opening of the anchor rod hole can result in insufficient grouting pressure, leading to incomplete grouting.

- Installation of anchor rods is time-consuming and labor-intensive.

- When using the method of installing the anchor rod before grouting, pulling out the grouting pipe may result in the loss of grout, unnecessary wastage, and also impact the quality of grouting.

Construction of Self-drilling Anchor tools

The self-drilling anchor tool integrates drilling, grouting, and anchoring into a single process, allowing for time-saving construction. It offers the following advantages:

- Suitable for challenging drilling conditions: In cases where the surrounding rock is relatively loose or fragmented, conventional drilling can be difficult and prone to hole collapse. It becomes challenging to insert other anchor rods or cables into the hole. The self-drilling anchor system overcomes these limitations. After drilling is completed, the anchor bolt remains in the hole without needing to be removed. This eliminates the risk of hole collapse, saves time required for inserting other rods, and reduces construction difficulties.

- High adaptability: The entire body of the self-drilling anchor bolt has threads, allowing for cutting and extending at any position to accommodate different construction conditions.

- High anchoring strength: The self-drilling anchor bolt has an R-type or T-type thread, ensuring a secure connection with the coupling sleeve and excellent bonding with the grout.

- Effective anchoring: During grouting, as the grout is injected from the bottom of the hole upward, it guarantees complete grouting, good compactness, and high grouting quality.

- Easy construction: Compared to conventional anchor rod construction, the self-drilling anchor system reduces the need for drilling, installing anchor bolt, and inserting grouting pipes. This simplifies and expedites the construction process.

The construction principle of the self-drilling anchor system

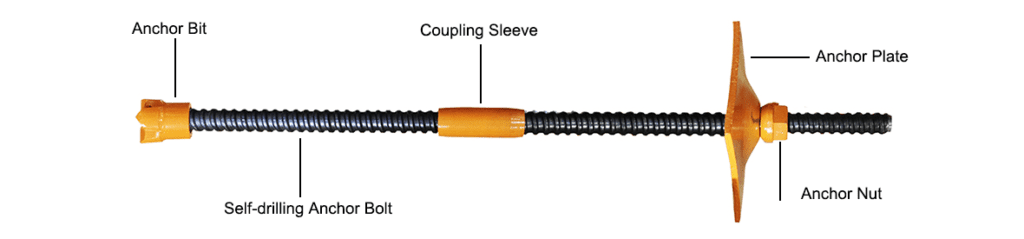

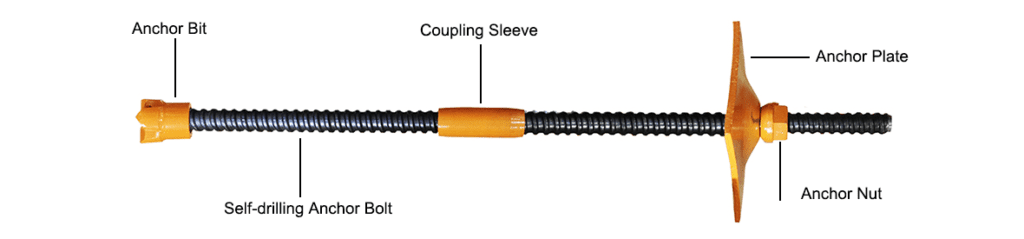

The self-drilling anchor system mainly consists of a self-drill anchor bit, self-drilling anchor bolt, coupling sleeve, plate, nut, and grout plug. If the length of the anchor bolt is shorter than the design depth, a coupling sleeve is used to connect and extend the anchor bolt. The anchor drill bit is made of a material with strong penetration capability, allowing the anchor rod to penetrate various types of rocks. The self-drilling anchor rod body is threaded, facilitating the installation of the anchor bit, coupling sleeve, and nut. The grout plug maintains a certain pressure during grouting, ensuring thorough filling of the rock voids with grout. The nut concentrates the surrounding rock stress onto the anchor plate.

The self-drilling anchor bolt is connected to the drilling head at one end and can independently complete the drilling task under the action of the drilling rig. The outer surface of the anchor bolt body is designed with continuous threads, which can solve problems such as poor debris discharge, hole collapse, and sticking during drilling, thereby increasing the gripping force of the anchor bolt. At the same time, the high-strength anchor bolt significantly enhances the stability of slope engineering. The hollow body of the anchor bolt serves as a grout conduit. After drilling, cement slurry is injected from the cavity of the hollow body, filling and solidifying around the rod when the cement slurry fully encapsulates the rod, providing overall reinforcement. The outer end of the anchor hole is equipped with a grout plug and a anchor plate, effectively preventing the overflow of grout and ensuring the complete grouting between the rod body and the hole wall. This allows for the transmission of shear and tensile stresses along the anchor bolt, ensuring the reinforcement of the rock mass within the anchor zone. If necessary, pressure grouting can also be implemented to allow the grout to penetrate and diffuse into the cracks of the surrounding rock mass, further reinforcing the rock mass within the anchor zone.

After the grout has solidified, tightening the nut forms a spherical pressure zone at the junction of the nut’s curved shape and the anchor plate. This allows for controlled initial deformation of the rock mass after excavation, preventing the detachment of fragmented rock blocks and significantly enhancing the stability of tunnels or slope engineering.

The anchor bolt not only ensures complete grouting within the gap between the rod body and the hole wall but also, due to the inclusion of an anchor head, grout plug, and coupling sleeve, allows the rod body to be centered within the anchor hole. This ensures that the anchor rod obtains a uniformly required protective layer thickness, greatly improving its durability.

Illustration of the construction process of the self-drilling anchor tools

1, Drilling

Prior to drilling, the anchor bit is installed at the head of the self-drilling anchor bolt. The anchor bolt, equipped with the anchor bit, is advanced forward using a drilling machine. If the length of the anchor bolt is insufficient, a coupling sleeve is used for extension before drilling continues. Approximately every 60cm of drilling, the drilling process is paused to remove drill cuttings through flushing.

2, Grouting:

After completing the drilling, install the grout stopper. The grout stopper is installed 25cm away from the hole opening. In special cases where the grouting pressure is high or the surrounding rock is too fragmented, grout adhesive can also be used for fissure grouting. Subsequently, connect the tail end of the anchor rod to the grout pump using a quick grouting joint and proceed with grouting.

3, Installation of anchor plate and nut:

To enhance the anchoring force between the anchor bolt and the concrete retaining wall, it is necessary to install an anchor plate and securely connect it to the anchor rod using a nut.

In slope stabilization projects, self-drilling anchor tools have the advantage of strong drilling penetration, making them suitable for various types of rock. The threaded body and high-strength coupling sleeve of the anchor bolt enable it to be drilled and extended simultaneously, making it convenient for reinforcing narrow construction spaces. Compared to conventional anchor rods, self-drilling anchor tools have greater adaptability. They do not require the removal of anchor rods, avoiding the need for grouting or tube installation in the borehole, thereby improving construction quality and saving overall construction costs.